How it all began

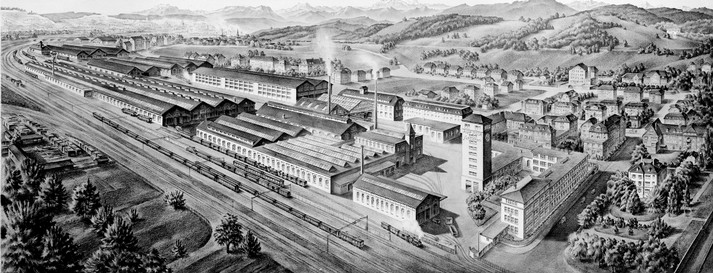

On March 14, 1895, Johan Caspar Geissberger submitted an application to purchase around 39,600 square meters of land to the Schlieren local council. The purchase contract was concluded and the groundbreaking ceremony took place on May 18th of the same year. The area bordered on the route of what was then the Nordostbahn. Geissberger built generously designed workshops on this property.

On the one hand, the company Geissberger & Cie intended to put

the production of luxury cars, trucks, sleighs and the refinement of wagon wheels in Schlieren on a broader basis. On October 1, 1896, the previous sole proprietorship was converted into a limited partnership. In addition to J.C Geissberger, it also included his two sons Caspar and Robert.

In addition, the limited partners Julius Schwarzenbach and Konrad Jenny joined the company with a limited partnership contribution of 100,000 Swiss francs each. The expansion and design of the business went hand in hand with the conversion of the previous limited partnership into a stock corporation. On that Thursday, November 29, 1899, at 2:30 p.m. in the afternoon, the

constitutive general meeting of Geissberger & Cie took place in the Hotel Baur au Lac in Zurich. The then new stock corporation was registered in the commercial register on December 19, 1899.

1901 - 1920

In 1901, Geissberger & Cie. The part of the luxury horse-drawn carriages in Schlieren that had been taken over was definitely discontinued and the focus was now on building rail vehicles. A new line of business that, on the one hand, became very lucrative through the construction of a large number of electric narrow-gauge railways, as well as the conversion of the then Zurich city tram to electric operation.

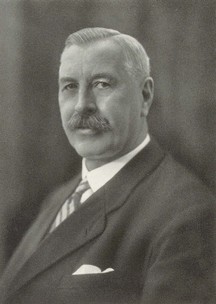

For this reason, the name was further changed to Schweizerische Wagonsfabrik A.G Schlieren in 1901. The concentration on wagon construction and the associated change in the production program also led to a change in the composition of personalities that have been significant since the company was founded. This is the point in time when the effectiveness of a man became apparent, who from then on had a decisive influence on the history of the company: the director Josef Koch.

After steadily increasing orders and deliveries to tram companies and the Swiss railway companies that were still divided at the time, the newly founded Swiss Federal Railway SBB ordered 12 three-axle passenger cars, 2nd and 3rd class, in Schlieren in 1903. This first order from the federal railways also triggered a sharp increase in incoming orders. Construction activity at the Schlieren plant was also pushed forward. In 1906, an SBB C3ü became the one thousandth railway car to leave the Schlieren factory. In 1906 the young company's first strike occurred. The woodworkers stopped work for six weeks on February 24, 1906, shortly after payday.

Foreign railway companies have already ordered their first rail vehicles from SCHLIEREN. The first four-axle cars were delivered to Constantinople for the Oriental Railways and later for the Bern-Lötschberg-Simplon Railway. During the First World War, SCHLIEREN took over the elevator business of what was then the Seebach AG elevator and wheel factory (ARSAG). Between 1918 and 1919, the engineers in Schlieren, under the leadership of aviation pioneer Adolf Schaedler, managed to plan and realize the SWS C-1, which was also the first entry into aircraft construction in Schlieren.

1921 - 1940

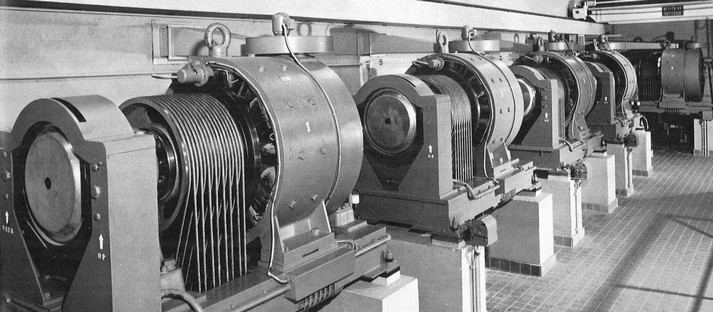

As early as 1924, SCHLIEREN was the first company in Europe to equip its elevators with so-called traction sheave drives. This technology was recently developed in the USA. Thanks to a license agreement, we were able to further develop this technology in Europe. In 1928, a meeting decided to change the name of the company again. With this change, the new core business of elevator construction was given a permanent position in our company. In 1928 the company was named Schweizerische Wagons- und Aufzügefabrik AG Schlieren - Zurich.

The years 1929 - 1930 brought full employment. The constantly increasing sales required the expansion of our workshops in Schlieren and the technical offices. Also in 1930, our developers achieved a world first in elevator construction. The first elevator control that runs on direct current. This development gave SCHLIEREN international reputation.

The lightweight steel design for passenger carriages, which was largely developed by SCHLIEREN, was quickly considered a groundbreaking development in carriage construction. A prototype light steel car was created, which was delivered to the SBB and other private railways in series from 1937. The first license construction order from Germany for an escalator to Holland was particularly important in the years 1936 - 38.

It should be the foundation for our company's third core business in a later phase. In 1937 we delivered the world's highest elevator to the Jungfraujoch / Sphinx. With the start of the Second World War in 1939, the first crisis slowly set in. Competition and the fluctuating order situation also affected SWS in the following years. Nevertheless, SCHLIEREN, together with the Schweizerische Industrie-Gesellschaft (SIG) in Neuhausen am Rheinfall, covered practically the entire domestic demand for railway wagons.

1941 - 1960

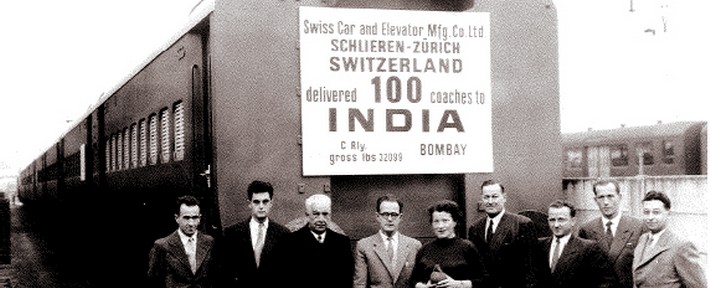

Another milestone followed in the first post-war years. Through a cooperation agreement between the Indian State Railways and the management of SCHLIEREN, a major order was realized in India in 1949 under the then technical management of "Heinrich Saxer König". Our company was significantly involved in the planning and implementation of a new wagon factory in Perambur (India). In 1955, the Intergral Coach Factory ICF was finally able to start operations in India. The Indian state railways ordered around 200 passenger coaches based on light steel in advance, which were manufactured in Schlieren.

Our company now employs around 2,000 people at the factory. The core business continued to be the construction of rail vehicles, elevator systems and component production in aircraft construction. In 1952 we brought the Variotron drive for elevators onto the market. It was the first electronically regulated elevator in the world. This system accelerated and decelerated the elevator's movement continuously and controlled the speed according to a precisely prescribed program.

In a competition organized by the SBB in 1954 among Swiss wagon building companies, the aim was to combine the most proven and the most advantageous of the previous wagon types in a new wagon and to find a design that would make series production technically feasible and affordable let. As the winners of this competition, SWS and SIG received the order to produce two prototypes each in February 1955, and within a year the two cars, which became known as the Standard Car I, were created.

In 1955 the punch card procedure was finally introduced for internal accounting, and in 1956 it was announced that Pars-Finanz AG (Schindler Group) was buying 30% of the share capital. In 1957, the elevator construction department once again achieved a top technical achievement with the construction of the new monotron drive for elevator systems. The first articulated trolleybus in Switzerland was developed in 1956 together with the BBC and FBW in Schlieren and delivered to the Winterthur and Zurich transport companies. It was a notable success for the designers at the time, as the trolleybus allowed for better scheduling of working hours and thus more favorable leisure conditions for the staff. In Schlieren, the test series and the entire development of car construction were significantly advanced.

In 1955 the punch card procedure was finally introduced for internal accounting, and in 1956 it was announced that Pars-Finanz AG (Schindler Group) was buying 30% of the share capital. In 1957, the elevator construction department once again achieved a top technical achievement with the construction of the new monotron drive for elevator systems. The first articulated trolleybus in Switzerland was developed in 1956 together with the BBC and FBW in Schlieren and delivered to the Winterthur and Zurich transport companies. It was a notable success for the designers at the time, as the trolleybus allowed for better scheduling of working hours and thus more favorable leisure conditions for the staff. In Schlieren, the test series and the entire development of car construction were significantly advanced.

Two important productions occurred between 1957 and 1958. In 1957, SCHLIEREN delivered the Monotron elevator control for the first time. Monotron could be viewed as a cornerstone of elevator construction. At the same time, it was the first success of joint research by Schindler / SCHLIEREN. In 1958, still based on the Variotron, the engineers in Schlieren achieved what was probably the biggest coup in the international elevator business. We were able to prevail against competitors, including OTIS, and were awarded the contract for a high-speed passenger elevator for the Atomium in Brussels, which was built for the 58 World's Fair. Just one year later, in 1959, we brought the Aconic control system for elevator systems onto the market. A system with semiconductor technology and no moving parts.

1961 - 1970

Schindler, which was also established in elevator and carriage construction, took over the company just four years later in 1960. From now on, the Schlieren location was retained as an independent group company of the Schindler Group despite the commissioning of the new Schindler Aufzüge AG location in Ebikon LU. However, the elevator construction division continued to be affiliated with the Schindler Group, particularly in terms of research. As a now unified company, Schlieren and Schindler covered well over 50% of the market share.

In 1961, SCHLIEREN brought the Econom elevator onto the market. The elevator was a series product with the stamp of one-off production. Standardized and prefabricated in all parts, this elevator represented the latest state of technical development at the time. At the same time, it combined everything that had long been tried and tested in elevator construction. Series production not only allowed for the shortest delivery times; It had an extremely favorable effect, especially in terms of pricing. Appropriate standardization made it possible to increase production numbers, reduce production times and simplify warehousing.

At the Geneva Motor Show in 1963, a SCHLIEREN lifting jack system for road and rail vehicles was presented to the public for the first time. The lifting jacks had already been used many years previously in our own factory in Schlieren for our own use. Through a study, these were shown for the first time as series production for the market. In 1964, the aircraft construction department was able to accept a large license order. The Swiss Air Force ordered its new Mirage III/RS fighter jets. Consequently, fuselage and wing parts for the Mirage were manufactured in Schlieren.

In 1961, SCHLIEREN brought the Econom elevator onto the market. The elevator was a series product with the stamp of one-off production. Standardized and prefabricated in all parts, this elevator represented the latest state of technical development at the time. At the same time, it combined everything that had long been tried and tested in elevator construction. Series production not only allowed for the shortest delivery times; It had an extremely favorable effect, especially in terms of pricing. Appropriate standardization made it possible to increase production numbers, reduce production times and simplify warehousing.

At the Geneva Motor Show in 1963, a SCHLIEREN lifting jack system for road and rail vehicles was presented to the public for the first time. The lifting jacks had already been used many years previously in our own factory in Schlieren for our own use. Through a study, these were shown for the first time as series production for the market. In 1964, the aircraft construction department was able to accept a large license order. The Swiss Air Force ordered its new Mirage III/RS fighter jets. Consequently, fuselage and wing parts for the Mirage were manufactured in Schlieren.

1971 - 1985

In 1970 we expanded our production field and built the first reflector for solar research for ETH Zurich. In 1973 we built the first 3-dimensional conveyor system together with the Schindler subsidiary "Von Roll Förderanlagen AG". This in turn laid the foundation for product expansion. The demand for conveyor systems increased enormously during this time and resulted in high order intake from the manufacturing companies. Also in 1973, the contract was signed with EUROFIMA for the construction of 63 T2S sleeping cars for various European state railways. Our company was a leader in the development and construction of this type of sleeping car. The S in the name therefore also stands for streaks.

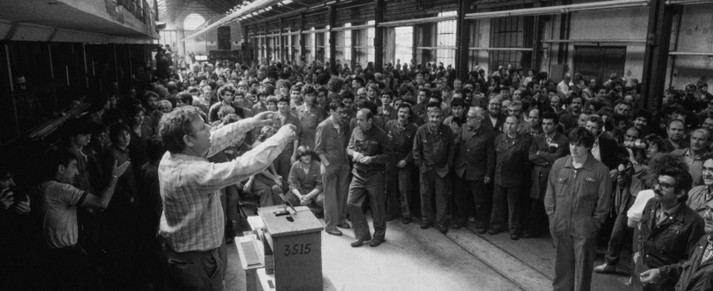

On May 16, 1983, the Schindler Holding Board of Directors officially announced that the Schlieren factory would be closed after over 14,000 freight and passenger cars had been produced. The employees, the municipality and the canton of Zurich initially did not want to accept this decision from Ebikon. There was massive debate on the street and in politics against the closure decision. Swiss television broadcast its own documentary program to mark the closure. The canton of Zurich even threatened to withdraw current orders from the Schindler Group.

On May 16, 1983, the Schindler Holding Board of Directors officially announced that the Schlieren factory would be closed after over 14,000 freight and passenger cars had been produced. The employees, the municipality and the canton of Zurich initially did not want to accept this decision from Ebikon. There was massive debate on the street and in politics against the closure decision. Swiss television broadcast its own documentary program to mark the closure. The canton of Zurich even threatened to withdraw current orders from the Schindler Group.

The city of Schlieren, the canton of Zurich and Schindler finally agreed on an agreement on "Open Planning SWS". This was intended to use the factory area in such a way that almost the same number of jobs could be created in different professional sectors and new companies. Together with the above-mentioned agreement on open planning SWS, Schindler Holding made around 20 million Swiss francs available. On August 31, 1985, “WAGI” was closed amid strong protests from employees and the public.

2016 - 2024

In 2016 - 31 years after the company closed - the WAGI Schlieren association was founded. This is with the aim of preserving the historical legacy of the Swiss wagon and elevator factory Schlieren for posterity. A small collection, which was stored in the basement of a school building, served as a starting point. In 2017, on the initiative of Patrick Bigler, the first museum was planned on the factory premises. Thanks to a collaboration with the city of Schlieren and the area owner, the Gewerbe- und Handelszentrum GHZ AG, the first small WAGI museum was opened at Wagistrasse 13 in September 2017.

The club continued to grow over the next two years. During this time, the collection was expanded to include additional exhibits and archives. However, the limited space prevented the Ais position from being expanded. The number of visitors also developed positively. At the end of 2019, the club was offered a new and larger location on the site. It is the former SWS boiler house. It was only thanks to a lot of negotiating skills and support that we were able to rent the property at Wagistrasse 15. This, in turn, with the support of Gewerbe- und Handelszentrum AG (GHZ) and the city of Schlieren, which today supports the association with an annual operating contribution of CHF 70,000.00.

Today's WAGI Museum is located in the eastern part of the former factory area of the Schweizerische Wagons- und Aufzügefabrik AG in Schlieren. Since 2020 it has been housed in the former heating and energy center and presents its exhibition on around 800 m2.

The club continued to grow over the next two years. During this time, the collection was expanded to include additional exhibits and archives. However, the limited space prevented the Ais position from being expanded. The number of visitors also developed positively. At the end of 2019, the club was offered a new and larger location on the site. It is the former SWS boiler house. It was only thanks to a lot of negotiating skills and support that we were able to rent the property at Wagistrasse 15. This, in turn, with the support of Gewerbe- und Handelszentrum AG (GHZ) and the city of Schlieren, which today supports the association with an annual operating contribution of CHF 70,000.00.

Today's WAGI Museum is located in the eastern part of the former factory area of the Schweizerische Wagons- und Aufzügefabrik AG in Schlieren. Since 2020 it has been housed in the former heating and energy center and presents its exhibition on around 800 m2.

The history of the building goes back to 1960. There, the former heating and energy center of the wagon factory was expanded to include a boiler house. Where our exhibition is now located, there were still large heating tanks until the company closed in 1985. After the association moved into the larger property in 2020, the building was first upgraded externally. Construction work on the new museum then began. To do this, numerous structural measures first had to be carried out inside. The new permanent exhibition will be presented on two floors. These must be accessible. The installation of a stair lift is also included in the planning.

Numerous construction works were carried out by club members on a voluntary basis. In some cases, however, a construction company also had to be hired. The largest construction work on the facade and in the building was completed in October 2020. In December 2020, club members began the first work on the interior. According to an existing concept, the first painting and plastering work was started. At the same time, the first backdrop walls were installed and floors and walls were painted.

The first exhibits from the museum collection could only be transferred to their new location slowly. After the first museum at Wagistrasse 13 was dismantled, these were temporarily relocated. So that all exhibits in the permanent exhibition have their place in the future, work began on building individual pedestals and wooden structures. These were all planned and set up by the club. Certain exhibits, such as the kitchen plucker of the RhB's former MITROPA hall car, required a little more planning. But the hull was also safely transported to its display location in the museum, where its exterior was gently restored.

The first exhibits from the museum collection could only be transferred to their new location slowly. After the first museum at Wagistrasse 13 was dismantled, these were temporarily relocated. So that all exhibits in the permanent exhibition have their place in the future, work began on building individual pedestals and wooden structures. These were all planned and set up by the club. Certain exhibits, such as the kitchen plucker of the RhB's former MITROPA hall car, required a little more planning. But the hull was also safely transported to its display location in the museum, where its exterior was gently restored.

Transporting and unloading the Ticino ABe 4/4 5 railcar was a little more complex. The club was able to save it from demolition in Grono at the last second. A location at the new museum had to be found quickly so that the railcar could have a long-term location. This hurdle could also be overcome. Today the railcar presents itself as a business card in front of the museum.